Industry-Grade Plastic Crates: A Comprehensive Buyer's Guide

Material Matters:

The first and foremost consideration in choosing plastic crates Sydney is the material. High-density polyethylene (HDPE) and

polypropylene are the most common materials used for industry-grade crates.

HDPE is known for its robustness and resistance to chemicals, making it

suitable for industries dealing with various substances. Polypropylene, on the

other hand, offers flexibility and impact resistance, making it ideal for

applications that involve frequent handling and transportation.

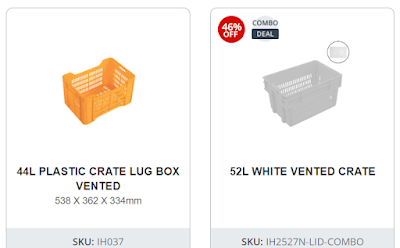

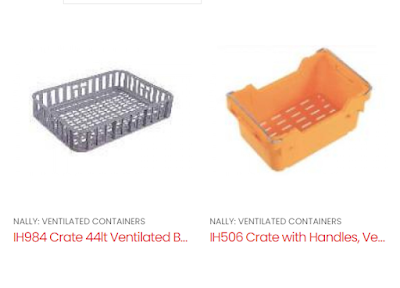

Design and Structure:

The design of mega bins Sydney directly

influences its usability and durability. Look for crates with reinforced

corners and ribbed walls, as these features enhance structural integrity and

prevent deformation under heavy loads. Ventilation is another crucial design

aspect, particularly for industries dealing with perishable goods.

Well-designed vents facilitate air circulation, preventing the buildup of

moisture and maintaining the quality of stored items.

Size and Capacity:

Choosing the right size and capacity of plastic

crates is essential to optimize storage space and transportation efficiency.

Assess the dimensions of your products and storage areas to determine the

appropriate crate size. Additionally, consider the load-bearing capacity of the

crates to ensure they can handle the weight of your goods. Investing in crates

with stackable and nestable features can further enhance space utilization

during storage and transportation.

Temperature Resistance:

Industries dealing with extreme temperatures or

varied climate conditions should prioritize plastic crates with

temperature-resistant properties. Some crates are designed to withstand a wide

range of temperatures, ensuring the integrity of the stored goods regardless of

environmental factors. This is particularly important in industries such as

food and pharmaceuticals, where temperature control is critical for product

safety.

Cleaning and Hygiene:

Maintaining cleanliness and hygiene standards is

imperative, especially in industries handling food, pharmaceuticals, or other

sensitive products. Consider for plastic crates with smooth, easy-to-clean

surfaces. Look for crates that are resistant to chemicals and can withstand

regular cleaning processes, including pressure washing. Ensuring the hygiene of

your plastic crates contributes to the overall safety and quality of your

products.

Customization Options:

Every industry has unique requirements, and the

ability to customize plastic crates can be a significant advantage. Some

suppliers offer customization options such as company logos, color choices, and

specific features tailored to your industry needs. Investing in crates that

align with your branding and operational requirements can enhance the

professionalism of your logistics processes.

Durability and Longevity:

While the initial cost of plastic crates may vary,

it's essential to consider the long-term durability and longevity of the

investment. Look for crates with a track record of enduring heavy usage without

compromising structural integrity. A higher upfront cost for durable crates can

translate into long-term savings by reducing the frequency of replacements and

minimizing the risk of damage to your goods.

Conclusion:

In the world of logistics and industrial operations, the choice of plastic crates may seem like a minor decision. However, investing time and consideration into selecting the right industry-grade plastic crates can significantly impact the efficiency, safety, and overall success of your business. By focusing on material quality, design, size, temperature resistance, cleaning capabilities, customization options, and durability, you can make informed choices that align with your specific industry needs. A well-chosen plastic crate is more than just a container; it's a key player in the smooth and reliable flow of goods within your business operations.

Comments

Post a Comment