The Versatility of Industrial Plastic Crates: A Comprehensive Guide

Industrial

plastic crates are the unsung heroes of countless industries, quietly

streamlining storage, transportation, and organization. But their impact goes

far beyond mere practicality. These seemingly simple plastic crates in Melbourne offer

a winning combination of durability, versatility, and efficiency, making them a

sustainable and cost-effective choice.

From

Warehouses to Farms: The Importance of Industrial Plastic Crates

Industrial plastic crates VIC have become

ubiquitous across various industries. In warehouses, they ensure efficient

product storage and retrieval. Manufacturing facilities rely on them for

housing parts and components. The food and beverage industry utilizes them for

transporting and storing everything from fruits and vegetables to finished

products. Even agricultural applications find them useful for harvesting and

transporting crops.

A World of

Options: Types of Industrial Plastic Crates

The world of

industrial mega bins Melbourne

isn't one-size-fits-all. Different designs cater to specific needs and

applications. Here are some of the most common types:

· Stackable crates: These crates feature ridges or lips

that allow them to be securely stacked on top of each other, maximizing

vertical storage space.

· Nestable crates: Designed to fit snugly inside each

other when empty, nestable crates save space during return trips or when

storage isn't needed.

· Foldable crates: These crates offer the ultimate

space-saving solution. When not in use, they can be folded flat, significantly

reducing their footprint.

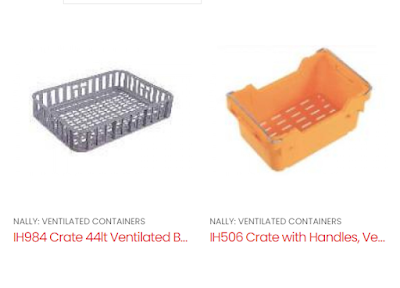

· Ventilated crates: Featuring openings or meshed

sides, ventilated crates allow for air circulation, preventing moisture

build-up and promoting freshness, particularly important for storing fruits,

vegetables, and other perishable goods.

Beyond

Functionality: Key Features and Benefits

Industrial

plastic crates boast several key features that contribute to their widespread

popularity:

· Durability and strength: Made from high-density

polyethylene (HDPE) or polypropylene (PP), these crates can withstand

significant weight and harsh conditions, ensuring long-lasting use.

· Lightweight nature: Compared to their metal or wooden

counterparts, plastic crates are significantly lighter, reducing transportation

costs and minimizing the risk of injury during handling.

· Resistance to chemicals and moisture: Plastic crates

are impervious to most chemicals and moisture, making them ideal for storing a

variety of products, including liquids and food items. They are also easy to

clean and sanitize, promoting hygiene and preventing contamination.

Applications

Across Industries: Where Plastic Crates Shine

The versatility

of industrial plastic crates extends to a wide range of industries:

-

Food

and Beverage: From storing fruits and vegetables to transporting finished products

like bottled drinks, plastic crates ensure safe and efficient handling of food

items.

-

Agriculture:

Used for harvesting fruits and vegetables, transporting crops, and storing

seeds and fertilizers, plastic crates play a crucial role in agricultural operations.

-

Automotive:

Parts and components used in vehicle manufacturing and assembly are often

stored and transported in sturdy plastic crates.

-

Retail

and Logistics: Retail stores and logistics companies rely on these crates for

efficient storage, organization, and transportation of various products.

A

Sustainable Choice: The Environmental Impact of Plastic Crates

Industrial

plastic crates contribute to a more sustainable future in several ways:

a.

Recyclability:

Most plastic crates are manufactured from recyclable materials, allowing them

to be repurposed into new products at the end of their lifespan.

b.

Comparison

with other materials: Compared to wooden crates, which can warp, rot, and

harbor pests, and metal crates, which are heavier and prone to rust, plastic

crates offer a more sustainable and long-lasting option.

Sustainability

Practices in Manufacturing

Many

manufacturers are implementing sustainable practices in the production of

plastic crates. This may include using recycled plastic content, minimizing

waste during the manufacturing process, and adopting energy-efficient

production methods.

Choosing the

Right Crate for Your Needs

Selecting the

perfect industrial plastic crate requires careful consideration of several

factors:

-

Size

and weight capacity: Ensure the crate can accommodate the size and weight of

the items you plan to store or transport.

-

Design:

Consider if stackability, nestability, foldability, or ventilation are

important features for your application.

-

Customization

options: Many manufacturers offer options for customization, including branding

logos and color.

-

Cost

considerations: While plastic crates are generally cost-effective, compare

prices from different suppliers while considering the crate's durability and

features.

Conclusion

Industrial plastic crates offer a compelling

combination of functionality, durability, and environmental consciousness. They

are a versatile solution for countless industries, streamlining operations,

maximizing storage efficiency, and promoting sustainability. By choosing the

right type of crate for your specific needs, you can optimize your operations

and contribute to a more sustainable future.

Comments

Post a Comment